Advanced Mold Release Solutions for Maximum Manufacturing Efficiency

Increase cycle times, reduce defect rates, and enhance surface finish. We partner with manufacturers in Southeast Asia and India to solve your toughest molding challenges.

Trusted by Leading Manufacturers Across Asia

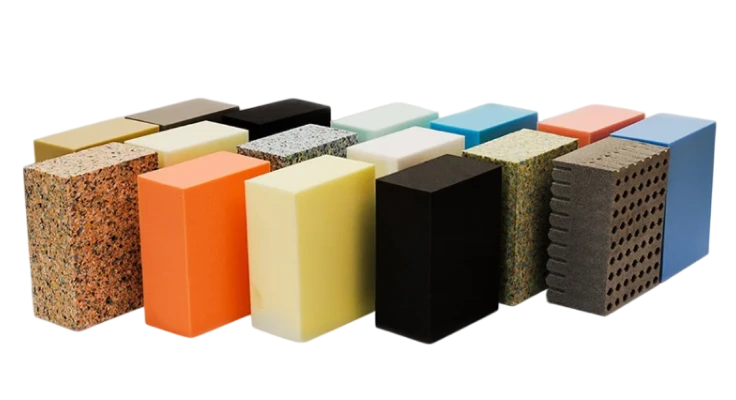

Explore our main product lines and their applications.

Increased Productivity

Multiple releases per application, reducing downtime.

Superior Surface Finish

Achieve flawless high-gloss or matte surfaces with zero transfer.

Sustainable Formulations

Environmentally friendly, reducing waste and energy consumption.

Expert Technical Support

Custom solutions for your specific application.

Find Your Perfect Release Agent by Application

Discover our comprehensive range of release agents tailored to your specific needs.

Polyurethane (PU) Molding

For footwear, furniture, and automotive interiors. Achieve perfect gloss and paintable surfaces.

View Products

Rubber Molding

For automotive components, footwear, and industrial applications. Ensure smooth demolding and high-quality surfaces.

View Products

Silicone Molding

For electronics, medical devices, and aerospace applications. Achieve high-precision and low-shrinkage parts.

View Products

Carbon Fiber Molding

For automotive components, aerospace, and industrial applications. Achieve high-strength and lightweight parts.

View Products

Concrete Molding

For construction, infrastructure, and industrial applications. Achieve high-strength and durable parts.

View Products

Other Applications

For a wide range of industries, including construction, aerospace, and medical devices. Achieve high-strength and durable parts.

View ProductsDriven by Innovation, Committed to Your Success

Advanced Technology

Next-Generation Formulations: Our R&D is dedicated to creating industry-leading release technologies.Sustainable Solutions: We engineer advanced water-based formulas that meet strict global environmental standards.Maximum Efficiency: Our semipermanent systems deliver hundreds of release cycles from a single application, dramatically reducing your downtime.

Our Partner in Process Optimization

More Than a Supplier: We don't just sell products; we deliver complete manufacturing solutions.Deep Process Understanding: Our technical experts work with you on your factory floor to solve your toughest challenges.Customized for You: We tailor our chemistry to lower your costs, improve your yield rates, and elevate your product quality.

Learning Hub

Stay updated with the latest industry insights and best practices.

T-2832 Paper Strengthening Agent Guide

Detailed guide for using T-2832 paper strengthening agent, including application process and quality control measures.

Innovations in Non-Ionic Surfactant Technology

The injection molding industry plays a key role in modern manufacturing. It allows for the mass production of high-quality plastic parts quickly. As demand rises in automotive, medical, consumer goods, and aerospace, picking the right mold manufacturer is important. The best U.S. firms shine by using technologies like multi-cavity molds and hot runner systems.

Latest Trends in Surfactant Industry 2024

Comprehensive analysis of the latest trends in the surfactant industry for 2024, including market overview, key trends, and future outlook.