Demolding Solutions for Complex Concrete Molds(PART 2)

In our previous blog post, we introduced the concept of special-shaped concrete molds and the challenges associated with their demolding. Today, we’re diving deeper into this topic to share our recommendations on how to tackle these demolding difficulties!

3. Recommendations for Solving Demolding Challenges in Complex Concrete Molds

3.1 Optimize Mold Structure Design

A well-designed mold structure is the first and most effective step in reducing demolding risks.

For complex-shaped concrete molds, increasing the draft angle is especially critical. Practical experience shows that a draft angle of 1°–3° on mold sidewalls can significantly reduce lateral bonding forces after concrete curing, making demolding easier. This is particularly effective for deep cavities, vertical surfaces, and intricate contours.

Sharp corners and right angles should be avoided whenever possible. These areas tend to cause stress concentration and paste accumulation, which not only increase demolding difficulty but may also lead to edge chipping or surface damage. Using fillets or smooth radius transitions improves demolding stability and ensures better surface integrity.

For highly complex concrete components, segmented or adjustable modular mold designs are strongly recommended. This structure allows stress to be released gradually during demolding, reducing overall pulling force. It is especially suitable for precast concrete elements, architectural decorative concrete, and complex curved components, helping improve production efficiency while extending mold service life.

3.2 Optimize Mold Surface Treatment

The surface condition of the mold directly affects the friction coefficient between concrete and the mold.

When conditions allow, it is recommended to polish the mold surface to a roughness of Ra ≤ 0.8 μm. A smoother surface effectively reduces mechanical interlocking and improves the continuity of the release agent film, thereby significantly lowering the risk of concrete adhesion.

For complex molds with extremely high demolding requirements or fair-faced concrete applications, functional surface coatings can be applied, such as superhydrophobic coatings or PTFE (Teflon) coatings. These coatings create a stable low-friction barrier, achieving near “zero-adhesion” demolding performance.

Such surface treatments are particularly effective for high-end precast components, architectural decorative concrete, and reusable molds, greatly reducing dependence on release agent consumption and manual intervention.

3.3 Improve Release Agent Selection and Application Process

Different mold materials require specific release agents, along with optimized application methods. Proper release agent selection is shown in the table below.

| Mold Material | Release Agent Type | Key Features |

|---|---|---|

| Steel Mold | Oil-based / Water-based Release Agent | Excellent isolation; ideal for heavy-duty formwork |

| Wood / Plastic Mold | Water-based Polymer Release Agent | Eco-friendly; reduces water absorption by the mold |

| Complex Surfaces | Fluorocarbon or Silicone-based Release Agent; Eco-friendly oil-based | Uniform film formation; zero residue |

Application Key Points:

Apply a thin and uniform coating (recommended dosage: 0.2–0.5 kg/m²) and avoid pooling. Ensure the release agent is fully dry before concrete pouring (approximately 20 minutes).

3.4 Control Concrete Quality

In the demolding of complex-shaped concrete molds, the properties of the concrete itself and the pouring method play a decisive role in demolding success. Scientific control of the mix design and construction process can significantly reduce mold adhesion and surface defects.

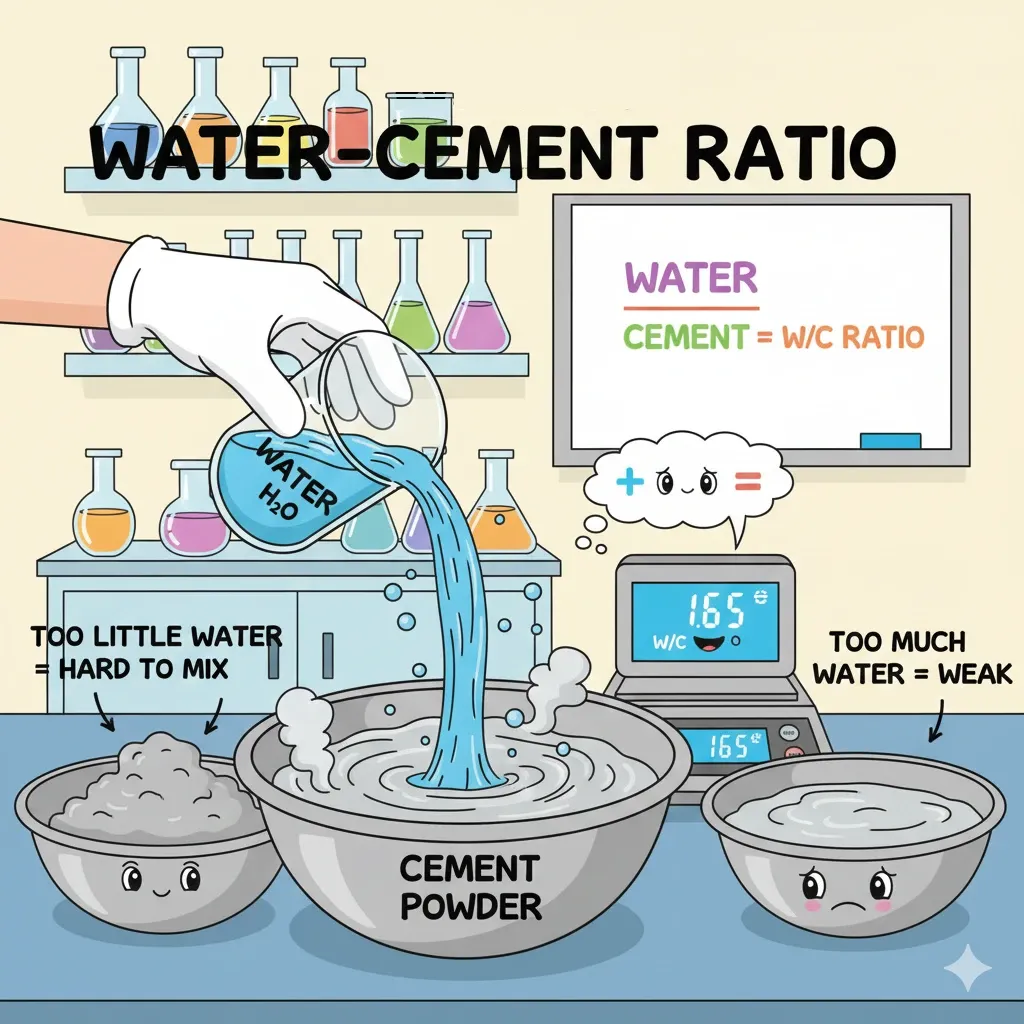

A proper mix design is the foundation for smooth demolding. Practical experience shows that maintaining a water–cement ratio between 0.4 and 0.6 ensures sufficient strength while preventing excessive stickiness or bleeding. A ratio that is too low increases cement paste adhesion to the mold surface, while a ratio that is too high may cause segregation and surface defects.

To improve workability without increasing water content, the use of high-performance water-reducing admixtures is recommended. This allows concrete to fully fill complex cavities, reduces vibration intensity, and lowers the risk of mold sticking.

For aggregate selection, the maximum size of coarse aggregate should not exceed one-third of the smallest mold dimension. Oversized aggregates tend to accumulate in narrow sections and corners of complex molds, negatively affecting surface quality and increasing demolding resistance.

3.5 Control of Pouring and Vibration Process

Correct pouring methods help form a uniform and dense concrete structure.

For complex molds, layered pouring is recommended, with each layer controlled at ≤400 mm. This effectively reduces lateral pressure on the mold caused by concrete self-weight and minimizes the risk of local bonding and deformation.

During vibration, high-frequency vibrators are recommended to remove air bubbles and improve surface compactness. Vibration should be uniform and moderate. Over-vibration may lead to bleeding or paste accumulation, increasing adhesion between concrete and the mold.

Direct impact of concrete on mold surfaces should be avoided, especially for thin-walled sections, complex curved areas, and decorative surfaces. Using chutes or controlled pouring methods helps protect mold coatings and release agent films from damage.

3.6 Proper Control of Demolding Timing and Techniques

Demolding too early or too late significantly increases the risk of failure and component damage.

Under normal conditions, side forms are recommended to be removed 3–7 days after pouring, provided the concrete strength has reached ≥1.2 MPa. At this stage, the concrete has sufficient self-supporting capacity without excessive bonding to the mold.

For **bottom forms and load-bearing formwork, demolding strength should be controlled according to structural span and design requirements, typically 75%–100% of the design strength. Larger spans and more complex load conditions require higher demolding strength to prevent deformation and surface damage.

During form removal, start from edges and non-decorative surfaces, gradually releasing stress before full demolding. For complex molds, light tapping with a rubber mallet, or assistance from a vibration table or mild mechanical vibration, can help reduce tensile stress on the concrete surface.

If stubborn local adhesion occurs, avoid using metal tools for prying. Instead, rinse mold joints with warm water, utilizing thermal expansion and lubrication effects to reduce interfacial bonding, ensuring safe demolding while protecting edges and surface quality.

3.7 Special Application Solutions

3.7.1 Demolding Recommendations for Complex Precast Pile Molds

Complex precast pile components are typically characterized by long lengths, variable cross-sections, and intricate internal cavities. During casting, high lateral concrete pressure significantly increases demolding risks.

A rigid–flexible composite mold structure is strongly recommended. The outer mold should use high-rigidity steel formwork to ensure dimensional accuracy and deformation resistance, while the inner mold should be made of flexible materials such as rubber or PU. During demolding, slight elastic deformation of the inner mold helps release gripping forces.

In the design stage, a controlled deformation allowance of 0.3–1.5 mm should be reserved to accommodate concrete shrinkage and volume changes during curing, preventing the inner mold from becoming “locked.” This solution effectively reduces inner mold extraction resistance, improves demolding reliability, and enhances production stability. It is widely applied in complex precast piles and special foundation components.

3.7.2 Demolding Solution for Fair-Faced Concrete Special-Shaped Columns

Fair-faced concrete special-shaped columns demand exceptionally high surface quality and detail integrity. Any cracking, bolt marks, or color inconsistency will directly compromise the final appearance.

For such applications, a custom mirror-finish panel combined with steel formwork is recommended. Mirror panels significantly reduce surface roughness, improving surface flatness and gloss, while steel molds provide structural stability and long service life.

To address tie-rod issues, mechanical connection systems are preferred over traditional welded or disposable through-wall tie rods. This approach enables non-destructive demolding, eliminating repair marks on the concrete surface and delivering a clean, uniform fair-faced finish. It is especially suitable for high-end public buildings and architectural decorative projects.

Conclusion

Stable demolding is not accidental—it is the result of systematic design and professional experience.

Demolding challenges in complex concrete molds are rarely caused by a single material or process failure. Instead, they result from the combined effects of mold structural design, surface treatment, release agent selection, concrete mix design, pouring and vibration methods, as well as demolding timing and techniques.

In high-demand applications such as complex geometries, undercut structures, fair-faced concrete, and precast components, failure in any single step can lead to mold sticking, surface defects, or mold damage.

Choosing a supplier with proven experience in complex concrete demolding, a mature product system, and on-site technical guidance capability is far more critical than simply comparing product prices. Only demolding solutions validated through extensive engineering practice can deliver consistent performance across different climates, mold materials, and concrete systems.

Marco Zhang

Co-founder & Product Engineer at Yunzhu

Identifying the right release agent shouldn't be a gamble. With 7+ years in chemical engineering, I help manufacturers in Concrete, PU, and Composites industries eliminate air bubbles and sticking issues. At Yunzhu New Materials, we don't just sell chemicals; we provide demolding solutions. We specialize in: 1.Water-based Concrete Release Agents (Eco-friendly & High Gloss) 2.Carbon Fiber & Composite Solutions 3.Custom formulation for specific temperature/mold requirements I bridge the gap between Chinese manufacturing efficiency and global quality standards. Whether you need a free sample test or technical advice on mold maintenance, feel free to reach out.

View LinkedIn Profile