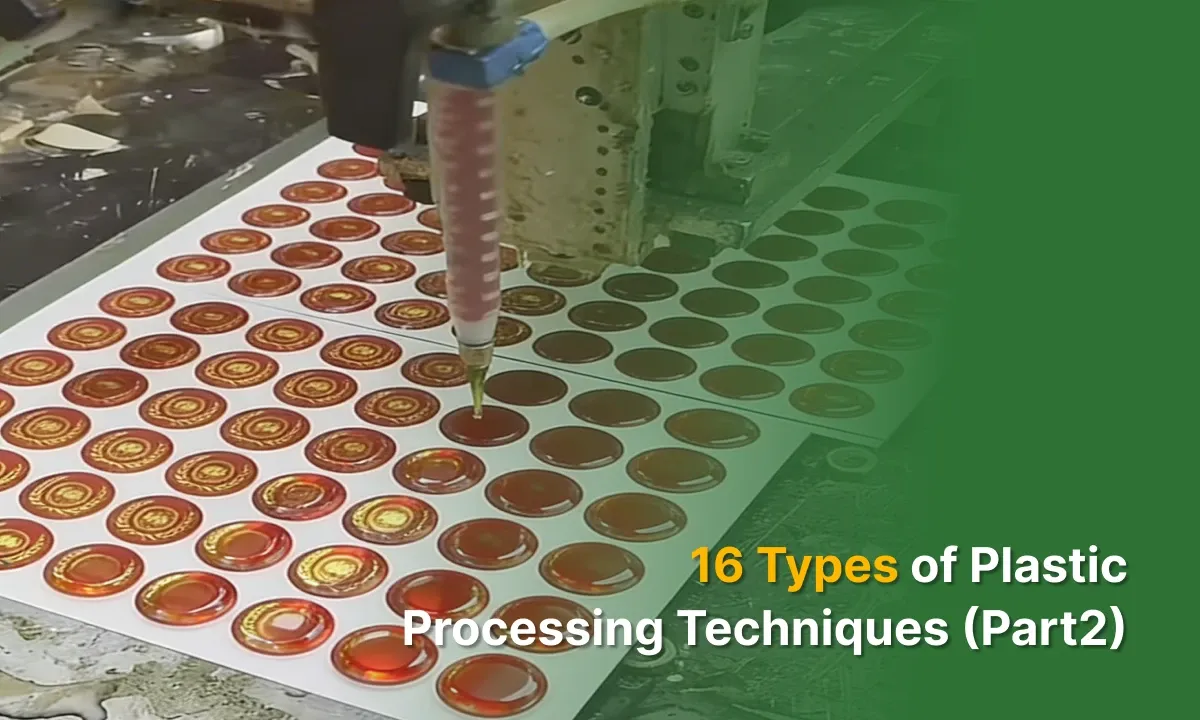

PU Foaming Technology:Principles & Applications

With the continuous advancement of materials engineering and industrial manufacturing, lightweight, high-performance, and functionally integrated materials have become key development trends across industries. Polyurethane materials, known for their high design flexibility and wide performance adjustability, show outstanding value in foaming applications. Polyurethane foaming technology enables weight reduction and energy efficiency while maintaining excellent mechanical properties, and plays a critical role in industries such as automotive, construction, electronics, and sports equipment. This article provides a systematic overview of the basic principles, production processes, and typical applications of polyurethane foaming technology in composite materials, helping readers better understand its technical characteristics and industrial prospects.