High-Resilience PU Foam Defects & Solutions for Automotive Seats

High-resilience polyurethane (HR PU) foam has become the most widely used foaming material for automotive seats and headrests due to its excellent comfort performance and cost efficiency. However, in actual production, factors such as raw material quality, process parameters, mold condition, and release agent selection often lead to defects including shrinkage, collapse, surface defects, tearing, and delamination, directly affecting seat appearance and overall quality. This article analyzes the manufacturing process of automotive PU foam, summarizes common defects in high-resilience polyurethane foam production, and provides practical solutions focusing on process optimization and PU foam release agent selection.

Defect 1: Foam Shrinkage

Foam shrinkage is one of the most common issues in high-resilience PU foam production for automotive seats. It typically appears as dimensional reduction, local deformation, or hardened edges, which can negatively affect assembly accuracy and seating comfort.

1.1 Cause Analysis

- Poor mold sealing: Insufficient sealing at the mold parting line causes material leakage, preventing the foam from reaching its designed density. Shrinkage may occur during demolding and cooling, often accompanied by hard edges near the parting line.

- Excessive gel catalyst dosage: Premature gelation increases cell wall elasticity, making proper cell opening difficult.

- High functionality polyether polyols: Accelerate three-dimensional network formation, increasing cell wall elasticity.

- Excessive foam stabilizer dosage: Overuse of silicone surfactants overly stabilizes cell structure, hindering effective cell opening.

- High isocyanate index: Further increases the tendency toward closed-cell structure.

1.2 Solutions

- Mold optimization: Improve sealing performance at the mold parting line.

- Formulation and process optimization: Rebalance catalysts by reducing gel catalysts (e.g., organotin) or moderately increasing amine blowing catalysts.

- Select polyether polyols with lower average functionality.

- Control foam stabilizer dosage within an appropriate range.

- Maintain the isocyanate index around 1.05.

- Post-processing: Apply mechanical crushing or compression immediately after demolding to force open closed cells.

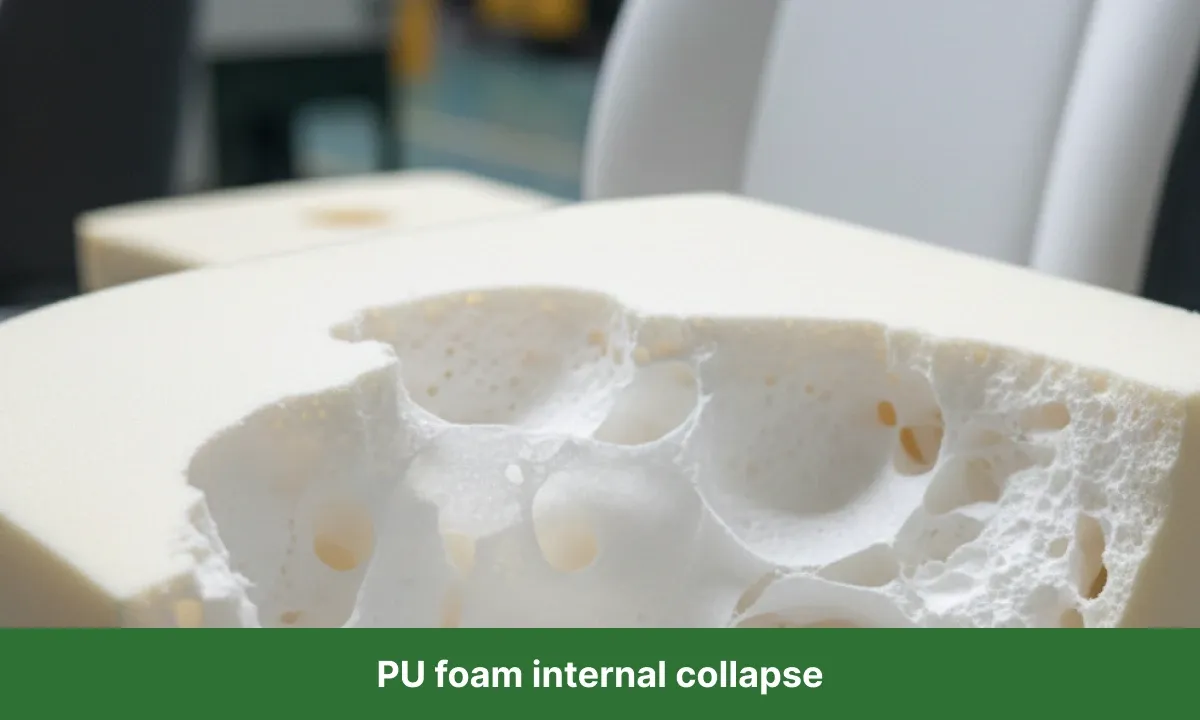

Defect 2: Internal Voids and Foam Collapse

This defect is characterized by local or overall internal voids and collapse, significantly reducing structural strength and resilience. It is a typical structural defect in automotive HR PU foam.

2.1 Cause Analysis

-

Imbalance between gelation and blowing reactions (core cause):

In HR PU foam systems, gelation and blowing reactions must remain highly synchronized.

If blowing proceeds significantly faster than gelation, large volumes of gas are generated before sufficient cell wall strength develops. This leads to cell rupture and interconnection, resulting in collapse; localized rupture manifests as internal voids. -

Insufficient or low-activity foam stabilizer:

Foam stabilizers are essential for stabilizing cell structure and delaying cell opening. Insufficient dosage or improper selection causes premature cell opening, gas escape, and collapse or void formation. -

Raw material quality issues:

Excessive acid value, high impurity levels, or low reactivity of polyether polyols disrupt reaction balance and increase the risk of voids and collapse.

2.2 Solutions

-

Optimize catalyst balance:

Increase gel catalyst dosage or reduce blowing catalyst levels to synchronize gelation and blowing reactions, ensuring adequate cell wall strength during gas generation. -

Enhance cell stabilization:

Increase foam stabilizer dosage or select high-performance silicone surfactants to stabilize cells and delay opening until reactions are substantially complete. -

Strict raw material control:

Monitor acid value, moisture content, and impurities of key raw materials to meet HR PU foam processing requirements.

Defect 3: Surface Defects (Pinholes, Roughness, Subsurface Voids)

Surface defects appear as visible pinholes, rough surfaces, or smooth subsurface voids beneath the skin, directly impacting appearance quality, tactile performance, and customer acceptance.

3.1 Cause Analysis

-

Poor mold surface condition:

Insufficient surface finish, contamination, wax buildup, improper vent design, or blocked vents prevent effective air release. -

Insufficient material flowability:

High blend viscosity (significantly above 1500–1800 mPa·s) or rapid gelation causes viscosity to increase too quickly, restricting uniform material flow. -

Improper process parameters:

Excessively fast foaming causes expansion before materials fully spread throughout the mold cavity. -

Pouring process and release agent issues:

Unreasonable pouring paths cause local material shortage; release agents may be insufficiently dried, unevenly applied, or mismatched with the foam system.

3.2 Solutions

- Improve mold surface finish: Thoroughly clean molds before production; inspect and clear vents to ensure proper placement at high points or parting lines.

- Reduce blend viscosity: Adjust gel catalyst dosage to maintain gel time within 55–65 seconds.

- Optimize blowing catalyst ratio: Extend cream time to 10–15 seconds; strictly control material temperature (22–24 °C) and mold temperature stability.

- Optimize pouring paths: Ensure uniform coverage; allow release agents to fully dry (air blowing or slightly increased mold temperature); select PU foam release agents compatible with the specific foam system.

Defect 4: Other Common Defects

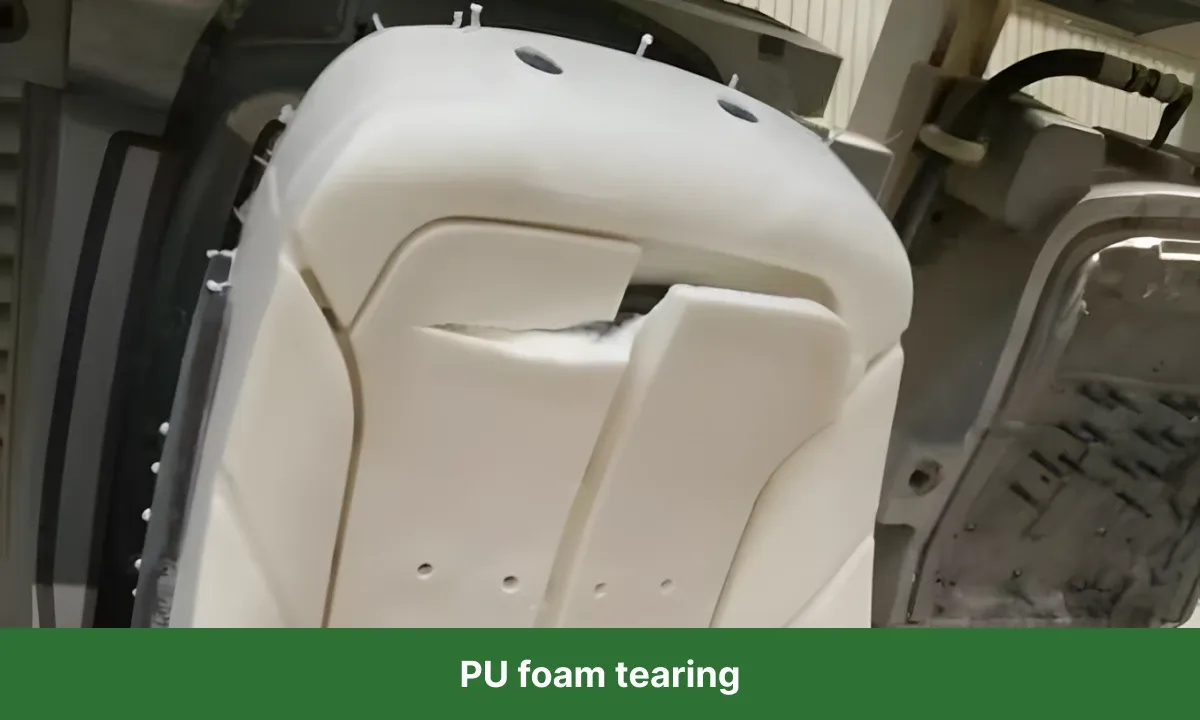

4.1 Tearing

- Main causes: Insufficient release force, low mold temperature, inadequate foam curing, improper demolding operation, or mold fouling.

- Solutions: Increase release agent application or switch to a higher-performance grade; raise mold temperature; reduce line speed or optimize formulation; standardize demolding procedures; clean molds regularly.

4.2 Blistering / Cracking

- Main causes: Excessive internal gas pressure and insufficient cell opening, combined with low release force, low mold temperature, insufficient curing, or improper demolding.

- Solutions: Increase open-cell silicone surfactants or cell-opening additives; optimize catalyst balance to promote timely cell opening; improve release agent performance or select a more suitable grade; raise mold temperature; improve curing conditions and demolding practices.

4.3 Internal Scorching

- Main causes: Reaction core temperature exceeding material heat resistance, often related to excessive moisture or impurities, high TDI index, high ambient temperature, or poor post-curing heat dissipation.

- Solutions: Strictly control raw material moisture and impurity levels; optimize formulation and balance chemical and physical blowing agents; improve ventilation and cooling during post-curing.

4.4 Delamination / Skin Peeling

- Main causes: Improper release agent selection (closed-cell tendency), low mold temperature, or insufficient formulation open-cell characteristics.

- Solutions: Select a compatible release agent; use pneumatic spraying instead of manual brushing; increase mold temperature; optimize formulation for improved cell opening.

Conclusion: Stable Foam Quality Requires Systematic Control

The production of high-resilience PU foam for automotive seats is inherently a system-level process that is highly sensitive to raw material quality, process parameters, mold condition, and release agent compatibility. Even minor deviations can be amplified into visible defects or structural failures.

In practice, manufacturers are advised to tailor solutions to their specific equipment and product designs, continuously validating and optimizing based on the defect diagnosis framework outlined above.

At the same time, selecting professional release agent solutions specifically engineered for high-resilience PU foam systems plays a critical role in improving product consistency, reducing defect rates, and lowering overall production costs.